ESD vs anti-static flooring: What’s the difference and which do you need?

In today’s high-tech workplaces, understanding the difference between anti-static and ESD flooring has never been more important. Whether you’re manufacturing sensitive electronics or wrapping pallets in a warehouse, choosing the right flooring can protect your people, your products, and your reputation.

At Ecotile, we offer a robust, guaranteed solution for static control: our ESD interlocking modular flooring. But let’s clear up the confusion – what’s the difference between ESD and anti-static flooring, and why does it matter?

The core difference: anti-static vs ESD

Let’s break it down:

Anti-static flooring

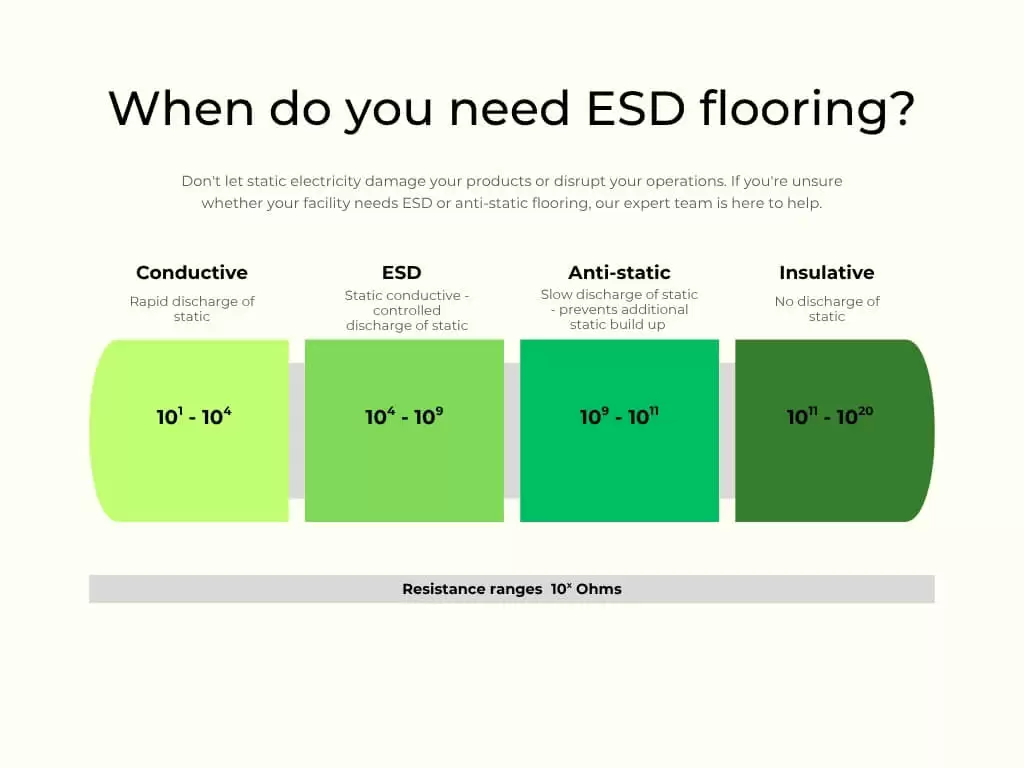

Anti-Static Flooring reduces the potential for static electricity to build up on the floor surface itself. It doesn’t generate static, but it won’t necessarily eliminate or dissipate static charges that have already built up elsewhere. Anti-static floors have a specific resistance range between 109 and 1011 ohms.

ESD (electrostatic discharge) flooring

ESD flooring is a fully integrated solution that is grounded to earth. It not only prevents static build-up but also continuously dissipates static electricity in a controlled manner. ESD flooring protects both people and sensitive electronic equipment from damaging discharges. ESD floors enable charges to be conducted through the flooring and safely to earth, so they offer a much higher level of protection over an anti-static floor.

What is anti-static flooring?

The term anti-static is often misunderstood and commonly requested by customer’s instead of ESD flooring. Anti-static flooring has a very specific electrical resistance range of between 10⁹ and 1011.

This only means that the floor itself will not generate static, it doesn’t mean that the floor will eliminate static build-up or dissipate static built up in the body.

In short:

➡️ Anti-static = passive prevention

➡️ ESD = active, guaranteed protection

When do you need ESD flooring?

You need ESD flooring when static discharge poses a risk to your products, processes, or people.

Examples include:

- SMT and circuit board manufacturing

- Electronics assembly and testing

- Medical device production

- Aerospace, automotive and telecoms facilities

- Cleanrooms and laboratories

- Data centres and telecoms facilities

In these environments, even a small discharge can cause irreversible damage to expensive and sensitive components. That’s why ESD flooring, with its consistent and certified path to earth, is essential.

Some facilities are required to have certified ESD flooring in place by industry standards and regulations.

Unexpected places static is a problem

More and more, we’re seeing static-related issues in areas you wouldn’t expect:

- Warehouses and distribution centres using automated pallet-wrapping machines: the friction from stretch film generates significant static, leading to painful shocks for operatives.

- Pick and pack stations with plastic trays, trolleys and packaging film: constant movement and low humidity create the perfect conditions for static to build up.

- Facilities with heating systems: warm, dry air reduces humidity, which increases the likelihood of static generation, especially when combined with plastic wheels on trolleys or synthetic footwear.

These environments aren’t traditionally thought of as “electrostatic-sensitive”, but the shocks and discomfort are real-and disruptive. An ESD flooring system can eliminate the problem at the source by dissipating the static.

When is anti-static flooring enough?

If you’re in an environment where static is more of an irritation than a danger or risk, anti-static flooring may be suitable. This includes:

- Office areas

- Light manufacturing

- General industrial spaces not working with static-sensitive equipment

It’s important to remember that anti-static flooring won’t remove static from people, tools, or equipment-it just won’t add to the problem. For environments where electrostatic buildup can cause equipment or product failure, ESD flooring is usually required.

Why Choose Ecotile ESD Flooring?

At Ecotile, we manufacture and supply guaranteed, fully earthed ESD modular flooring, designed for fast installation and long-term performance in demanding environments.

- Meets BS EN 61340-5-1

- Permanent, not surface-coated (ESD performance never fades)

- Installable over existing floors

- Modular, easy to move or change layouts

Our interlocking tiles are ideal for retrofit or new-build projects and are designed to last in heavy-duty environments.

Complementary ESD Protection Tips

Alongside ESD flooring, consider the following for maximum static control:

- Use ESD footwear or heel straps for staff working in ESD areas

- Maintain proper humidity levels where possible

- Clean your floors using anti-static cleaning products to avoid adding insulating layers

- Ensure equipment and workstations are correctly grounded

Need to eliminate static risk?

Don’t let static electricity damage your products or disrupt your operations. If you’re unsure whether your facility needs ESD or anti-static flooring, our expert team is here to help.

Contact us today for a consultation

Or visit our ESD flooring product page for full technical details

Static isn’t just a nuisance, it can be a costly problem. Let Ecotile provide the solution.

This post was originally published on 18 November 2019, it was last updated on 18 June 2025.