Ecotile X500/10 – The Ultra Heavy Duty Floor Tile

Our award-winning floor tile is also available in an ultra heavy-duty 10mm version. It’s packed with 42% extra thickness compared to our bestselling 7mm industrial tile. It’s designed specifically for environments where excessive forces and vehicles with heavy point loads are at work. Our 10mm floor tiles are engineered for incredible strength and performance in the most demanding settings.

Choosing the Right Tile For You

Ecotile’s 10mm ultra heavy-duty interlocking floor tiles are extremely tough. They can easily withstand heavy loads, high traffic movements and the rigours of exceptional industrial use.

However, our original and bestselling Ecotile 7mm tiles are the go to solution for most industrial environments. Used throughout the world, they enhance floors in factories, warehouses, workshops and even retail outlets.

When you have concerns about extremely heavy loads, X500/10 is the tile to specify:

- 3-wheeled forklifts (with heavy loads)

- Extermely heavy vehicles with tight turning circles

- Large forktrucks and frontloaders

- Narrow aisle stackers

- HGVs executing tight manoeuvres

- Aircraft

All Ecotile industrial floor tiles enable businesses to drastically improve the appearance and performance of high-traffic areas while offering excellent slip resistance, shock absorption and impact protection. Not to mention the class 1 fire certification.

Ultimate Floor Covering. Installed in Hours.

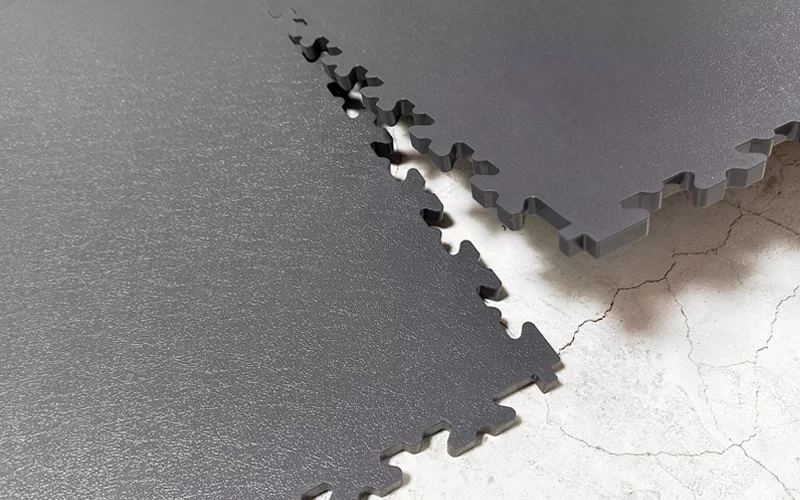

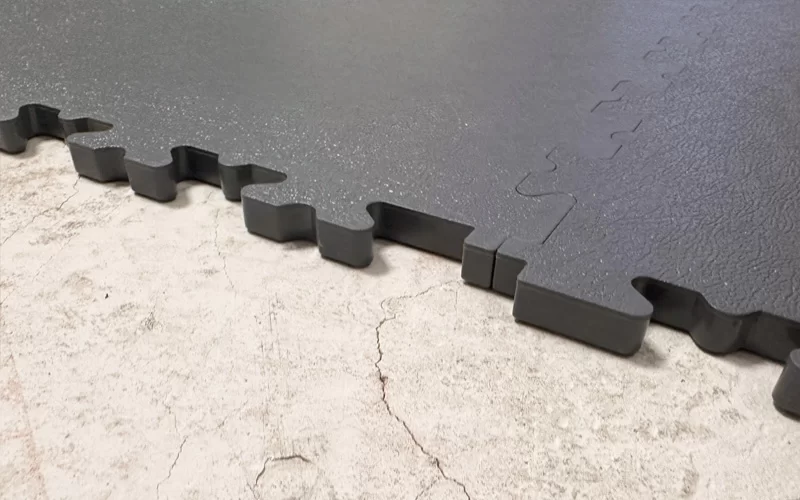

As with all Ecotile products, our 10mm tiles are designed to be loose-laid. Meaning they’re quick and simple to install. They can be fitted in sections, allowing you to continue operations during installation. And they’re ready to use immediately, without the curing or drying time associated with floor paints or screed. Plus, they’re perfect for areas where subfloors are more uneven and worn. So, you can save time on rectifying minor subfloor undulations too.

Choosing Ecotile means you can avoid the cost of continually repainting or repairing damaged and worn concrete. Especially prudent when leasing premises. Simply cover and protect your subfloor with Ecotile, and it’ll serve you well for 20+ years.

Next Level Floor Protection.

Covering worn subfloors with Ecotile reduces slips and trips. Not to mention preventing forklift accidents on uneven and crumbling floors. A fire-retardant rating of Bfl-S1 class 1 and an R10 slip rating enhances safety in industrial premises.

Ecotile’s 10mm heavy-duty tiles are perfect for:

- Manufacturing facilities

- Goods processing areas

- Loading bays

- Warehousing

- Aircraft hangars

- HGV workshops

Hard on wear, softer on the planet.

All Ecotile interlocking floor tiles are manufactured from 100% recyclable materials. So, at the end of their useful life, they can be returned to Ecotile and used to make our range of recycled tiles. We aim for zero to landfill, so we created the Ecotile Buy-Back and Take-Back schemes, designed to help businesses procure flooring more sustainably.

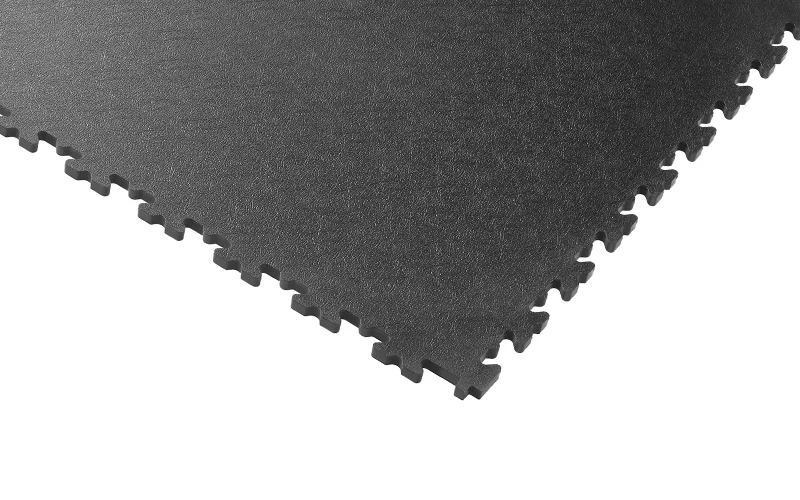

Finish: Smooth

Material: PVC

Joint: X-Lock

Dimensions: 497mm x 497mm

Thickness: 9.6mm variations +/- 0.3mm

Weight: 11.2kg/m2

Hardness: 90-92 Shore A

Sound Insulation Properties: Up to 46db

Fire Rating: Bfl-S1

Thermal Resistance Properties: R Value – 2.62 for 10mm Tile

- Engineering Plants

- Passenger Terminals

- Warehouses

- Commercial Garages

- Free Weights Areas

- Fire Stations

- Power Stations

- Distribution Centres

- Aircraft Hangars

- Maintenance Depots

- Suitable for extremely heavy vehicles

- Expected lifespan of 20 + years

- 10 Year warranty

- Good chemical resistance

- Install without downtime

- Noise reduction of up to 46db

- No damp proof membrane, screed or adhesives required

- Fire retardant – Class Bfl S1

- 100% recyclable

- Easy to maintain & clean

- Excellent slip-resistance (R10)

- Reduces worker fatigue

- Ideal for uneven or damp floors

- Quick & simple to install

Specification

Finish: Smooth

Material: PVC

Joint: X-Lock

Dimensions: 497mm x 497mm

Thickness: 9.6mm variations +/- 0.3mm

Weight: 11.2kg/m2

Hardness: 90-92 Shore A

Sound Insulation Properties: Up to 46db

Fire Rating: Bfl-S1

Thermal Resistance Properties: R Value – 2.62 for 10mm Tile