Industrial Flooring

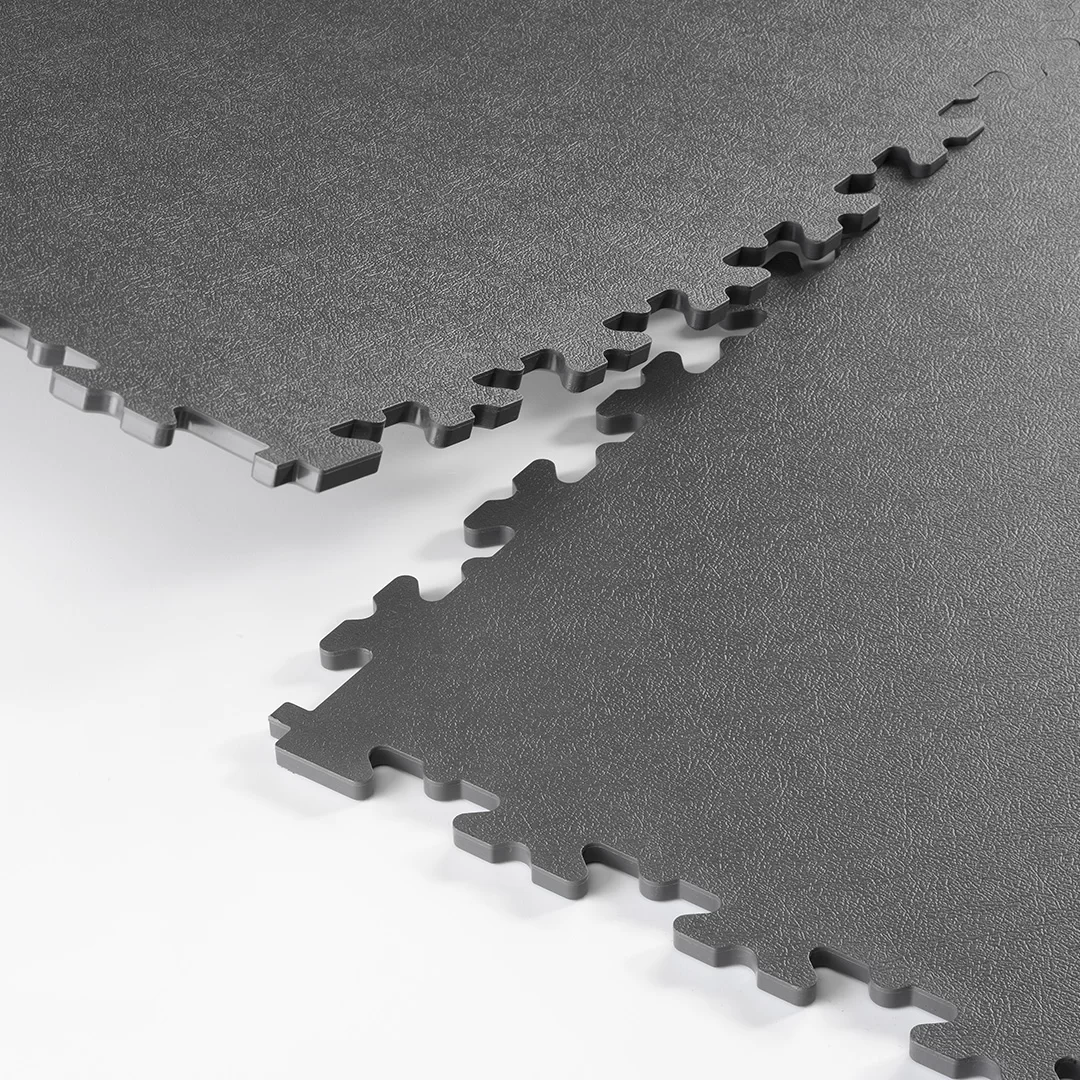

Interlocking PVC Floor Tiles. Engineered For Industry

Ecotile manufactures and installs interlocking floor tiles designed for demanding industrial and commercial environments. Made in our factory in Bedfordshire, our industrial flooring is designed to be laid over the existing subfloor without any adhesive or chemicals, eliminating the need for costly repairs and lost downtime.

Engineered for durability, our modular flooring system transforms industrial facilities and easily endures daily traffic from forklifts, pallet trucks and other heavy goods vehicles.

Our industrial flooring enables businesses to drastically improve the appearance of high-traffic floors, whilst offering excellent slip resistance, shock absorption and impact resistance in your facility. Not to mention class 1 fire certification. Our range of colours means they are also highly customisable for both aesthetics and safety.

Trusted by 1000s of Leading Businesses

Why Choose Ecotile Industrial Flooring?

10 Year Warranty

100% Recyclable

ESD Tiles Available

Protects Your Floor

Chemically Resistant

Easy & Quick to Install

Variety of Types & Colours

Reduces Dust and Noise

Slip Resistant

Variety of Products & Colours

7mm Tiles

ESD Tiles

10mm Tiles

Keep Your Business Moving

No Downtime Required

Easy to install in sections. No need to shut your operations down.

No Cure Time Needed

No need for glues or adhesives, so no waiting for drying / curing

Use Right Away

You can start using Ecotile immediately after installation

Improve Safety

Anti-Slip

Reduce slips and trips from uneven or worn surfaces

Pedestrian Walkways

Use different colours to create safe pedestrian walkways and zones

Permanent Safety Signage

Add-HSE compliant safety signage to your floor with logo tiles

Modular and Versatile

Adapt to Business Needs

Easily change layouts as your business evolves or repurposes

DIY Repair

Simple to replace tiles if damaged or changing colours

Move and Re-use

Lift, and move - leave the floor in tact. Perfect for leased units

Whatever Your Industry, There's an Ecotile For That

Manufacturing

Military & Defence

Transport & Logistics

Electronics & Assembly

Commercial Garages

Warehousing & Storage

Aerospace & Aviation

Commercial & Retail

Schools & Universities

Frequently Asked Questions

We always offer competitive quotes and recommend the most suitable tile for your needs.

We offer a wide range of tiles with varying thicknesses and strengths, designed to meet different needs. Contact us today for a free, no-obligation quote and an idea of pricing.

All Ecotile products have a 10 year manufacturer’s guarantee.

Our 7mm thick floor tile is our most popular solution for industrial and commercial use, and is suitable for vehicle use, including forklifts and pallet trucks.

Our 10mm thick floor tile is designed for very heavy industrial use. It’s recommended for use in areas where heavier fork trucks, aisle stackers or narrow aisle trucks are used. Ecotile E500/10 has also proven to be extremely successful in aircraft hangars and on fire station pump room floors.

All Ecotile products are designed to last for 10+ years.

Looking for a flooring solution that won’t cost you time and money in constant repairs and repainting? Consider Ecotile’s interlocking floor tiles instead of resin. Here are the top 5 reasons why Ecotile outshines epoxy and floor paint.

No, the subfloor does not have to be perfectly flat or without damage. Ecotile is an ideal solution for damp or worn floors. We may recommend patch repair if there are any areas of concern, but in 99% of cases, Ecotile can be installed without extensive repair work or preparation.

The surface texture of Ecotile offers an R10 anti-slip rating (prevents slips when wet or oily).

If large amounts of water are left to sit on the floor, it is possible that some will seep through the joint. The most common concern is that the water will become stagnant and start to smell, but this will not happen. Firstly the chemicals in PVC act as a natural biocide that prevents the growth of the bacteria that would make the water smell. Secondly, any moisture under the tiles will evaporate back up through the joint because the temperature above the tiles is almost certain to be higher than that under the tiles.