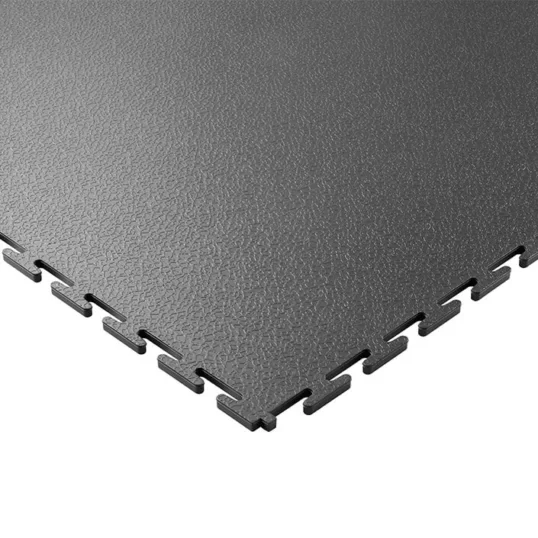

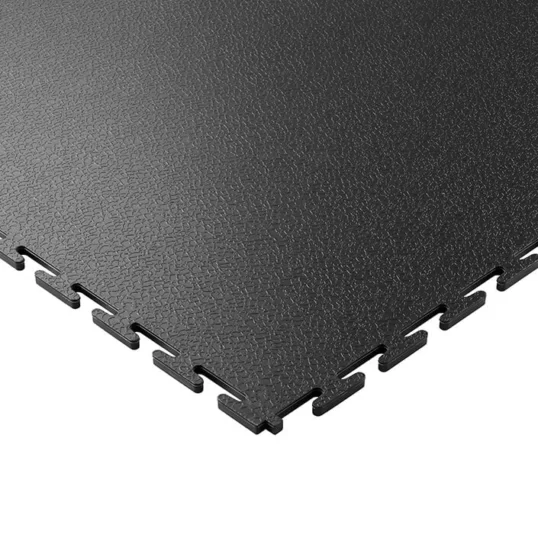

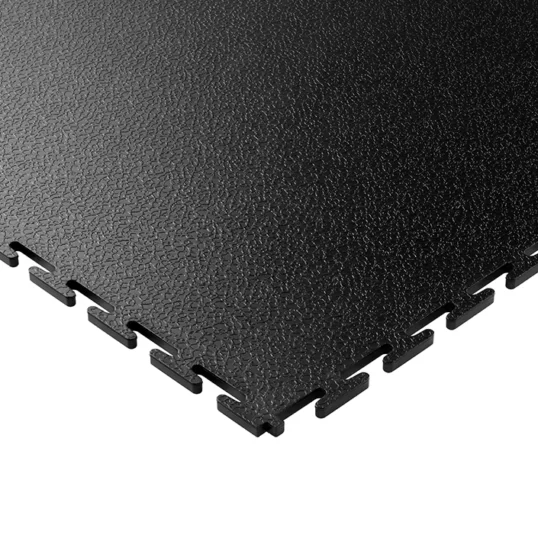

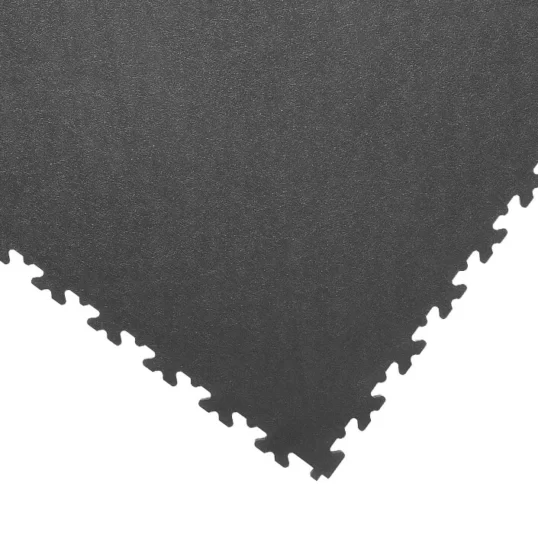

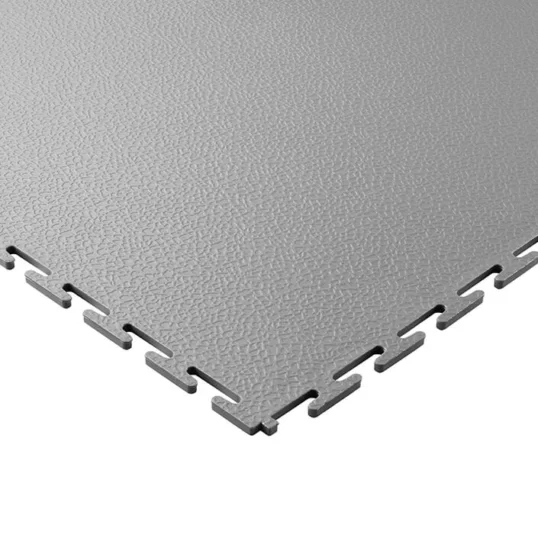

The original loose-lay interlocking floor tile

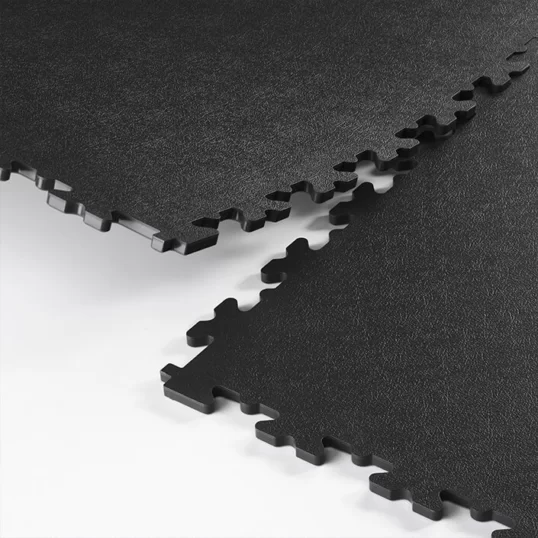

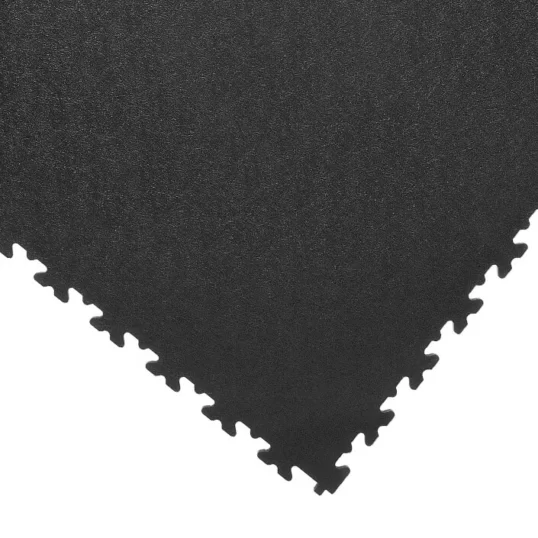

Available in two interlocking joint designs, our 7mm interlocking floor tiles are the go-to solution for most industrial applications, including factories, warehouses and commercial garages.

They deliver exceptional durability where it matters most, withstanding constant use by forklifts, aisle pickers, pallet trucks, pump trucks and heavy foot traffic.

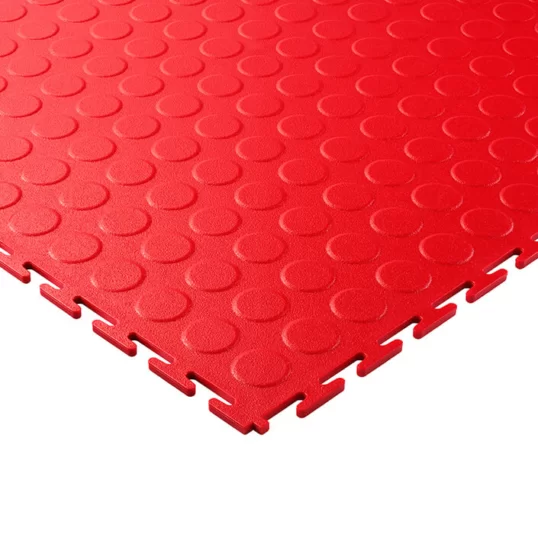

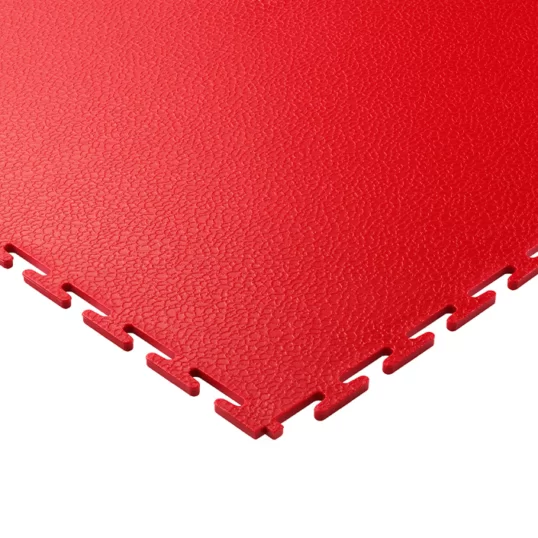

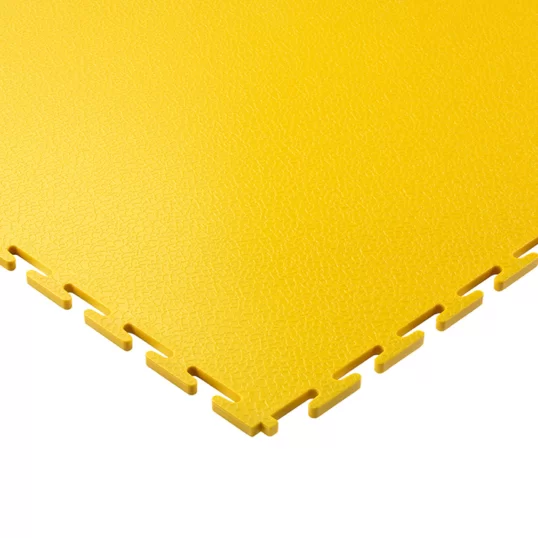

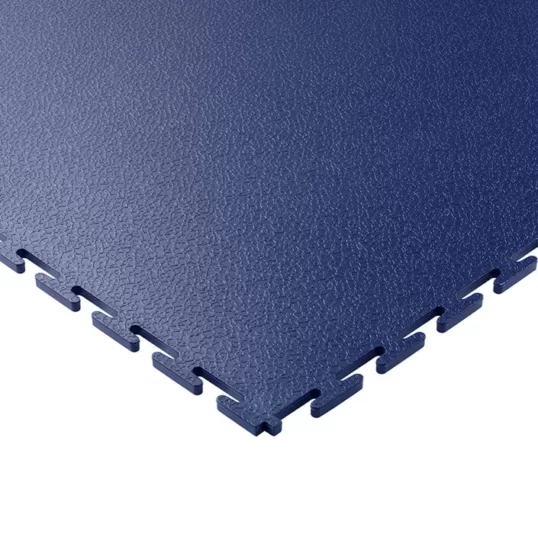

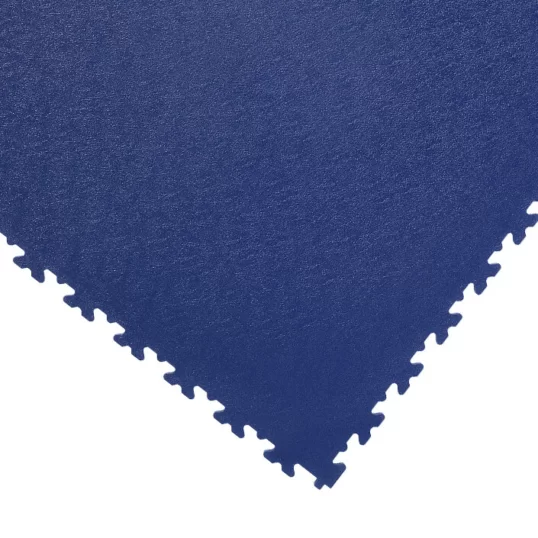

With an R10 slip resistance rating and Bfl-S1 fire classification, they help you maintain a safer working environment. With a wide range of colours available, it’s easy to create safety walkways and colour coded work zones around production lines, machinery, workstations and more.

The 7mm tile is our best-selling flooring solution used by hundreds of businesses worldwide, including Amazon, Royal Mail and Rolls-Royce.

- Impact resistant

- Chemical resistant

- Flame retardant (Bfl-s1)

- Abrasion and slip-resistant (R10 Rated)

- Suitable for heavy rolling vehicles and point loads

- Create coloured zoning and walkways

- Reduce dust and insulate from cold

- Easy to clean and maintain

- Hassle-free installation

- No curing times required

- 100% recyclable

Perfect for businesses who can’t afford to stop

Can’t put your business on pause just to redo the floor? Ecotile can be fitted with zero downtime – unlike epoxy resin, coatings and paints that can shut your site down for days.

Our interlocking floor tiles can be installed in sections without causing disruption. Your business can continue to operate whilst installation takes place directly on top of your original floor. You won’t need to move or recalibrate machinery and you can start using the new floor straight away.

Save time and money on concrete repairs

Eliminate the cost of repairing damaged and worn concrete for good. Install Ecotile over your subfloor without adhesives, damp-proof membranes or screed. Use our professional installation team, or install yourself.

Unlike other floor coverings, our modular floor tiles can be easily re-arranged to suit changing business needs. And if a tile gets damaged, no need to worry about calling an expert – just pop it up and replace it with a new one.

Protect the original subfloor

When you install Ecotile, there’s no need for nasty chemicals, adhesives or permanent coatings that damage the original floor. Whether you’re in a leased building or just want to protect your concrete subfloor from damage, the Ecotile interlocking system is a convenient solution. When it’s time to move on, the tiles can be lifted easily, leaving the concrete floor in it’s original condition – no landlord hassle or charges.

Recyclable and long-lasting

Our long-lasting interlocking floor tiles are designed to help you reduce costs and environmental impact. Once they reach the end of their useful 20+ year lifespan, we’ll collect or buy back your tiles and use them to make our range of recycled tiles.

Call +441582219009 or email [email protected] for a free, no-obligation quote and site survey.